3000L commercial beer brewing equipment

5000L beer brewing equipment

11/29/2017

2000L commercial beer brewing equipment

11/28/2017Set own brewery, start your beer business.

3000L commercial beer brewing equipment usually use it in beer factory, use steam heating for brewhouse..

Characteristic of 3000L commercial beer brewing equipment:.

80mm insulation by rock wool.

Top manhole.

Sight light .

4 pcs legs.

Stainless steel 304, 304L, or 316.

Thickness 3mm.

3000L commercial beer brewing equipment usually use it in beer factory, use steam heating for brewhouse..

Characteristic of 3000L commercial beer brewing equipment:.

80mm insulation by rock wool.

Top manhole.

Sight light .

4 pcs legs.

Stainless steel 304, 304L, or 316.

Thickness 3mm.

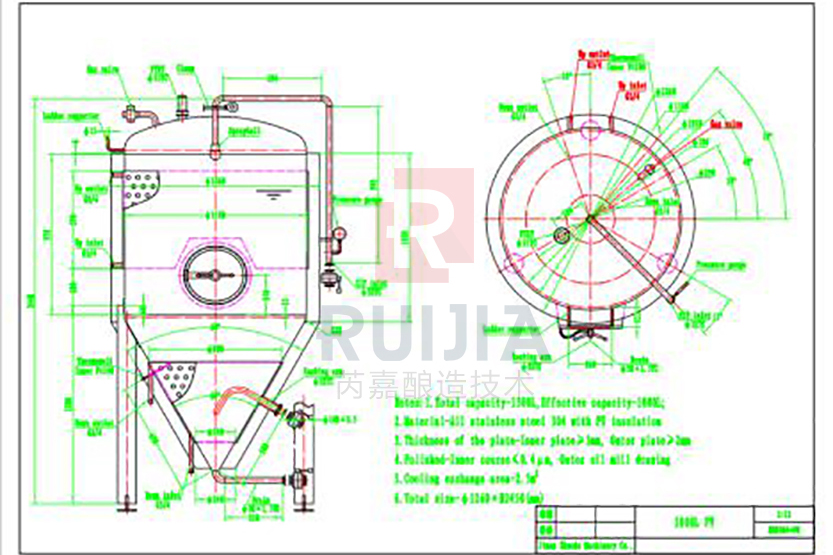

3000L commercial beer brewing equipment Product Parameters

| 3000L commercial beer brewing equipment | |||

| Brewing System | Components | Capacity | Specification |

| Milling System | Miller | 500KG/H | Double Roller/ 4 roller |

| Heating System | Boiler | 300KG/H | CE certification |

| Brewhouse System | Mash/Lauter tun | 3000L | Mashing Process:Decoction.Infusion.Multi-step infusion Heating source:Steam,Electric,Gas SUS304/Red copper |

| Brew Kettle/ Whirlpool Tank | 3000L | ||

| Hot Water Tank | 4000L | ||

| Heat exchanger | 20M2 | Stainless steel plate | |

| Fermentation System | Fermentation Tank | 3000L/6000L | Top manway/Side manway Drying hop port to brew IPA Dimple Plate Cooling jacket Carbonation port to fill CO2 |

| Yeast Adding Tank | 30L | SUS304 Stainless Steel | |

| Cooling System | Glycol Water tank | 10000L | Equiped with PU level indicator |

| Chiller | 15HP | UL/CE certified electric elements,Copeland compressor | |

| Pump | 5T/H | ||

| Cleaning System | Disinfection Tank | 300L | SUS304 full welded |

| Alkali Tank | 300L | ||

| Pump | 3T | ||

| Control System | Control Cabinet | PLC/digital | Semi-automatic/Automatic |

| Optional | Auger System | ||

| Grain Case | |||

| Grist Hydrator | |||

| Piping flow panel for Brewhouse | |||

| Brewhouse Separate PLC Controller | |||

| Customized | |||

| Technical Parameter | Power: Voltage:Cusomized Floor space: 50m2 | ||

Materials

Barley and hops is also very important part for beer, like IPA, it will need more strong hops. You can brewing many kinds of beer, we will also provide 10 kinds of beer recipe.Our service

Pre-sale service:

According to customer requirements to provide one-stop brewing beer project solution: tailored process flow chart; site layout; cost-benefit analysis.Production monitoring:

Equipment production will be strictly according to standards, timely communication with the customer production and other production conditions; to guide customers to prepare the venue; to help customers handle the relevant permit business procedures; equipment acceptance after the completion of timely and accurate delivery, contact the logistics do a good job Shipping matters.After-sales service:

Our commitment to all tanks five-year warranty, life-long technical support. And send professional brewing engineers free on-site guidance to install debugging; to teach brewing beer brewing technology; provide a variety of brewing brewing formula; supply all kinds of beer brewing raw materials.Notes:

1. Safe

The most import here is safe, when you operate the machine, please take your safe at first stage.2. Materials

Expect the good brewery equipment, please choose good materials, like hops and barley.3. Brewing water

Brewing water is very important for beer, it take 70%-80% in tank.If your taper water is not good, buy one water treatment is best.